Difference between revisions of "Joshpit's 4.0 Swap Article"

| (7 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

By AMC Eagle Nest Member Joshpit | By AMC Eagle Nest Member Joshpit | ||

| − | When You Give an Eagle a 4.0 Liter | + | <center> '''When You Give an Eagle a 4.0 Liter''' |

| − | + | ||

| − | + | '''She will ask for knobby tires.''' | |

| − | + | ||

| − | + | '''A complete Walkthrough for swapping a 4.0 into an AMC Eagle''' | |

| − | + | '''By: Joshua Tulberg''' | |

| + | |||

| + | '''[email protected]''' </center> | ||

| + | |||

| + | Here is the printable pdf version: | ||

| + | |||

| + | http://www.amceaglenest.com/images/PDFS/Joshs%204.0%20Walkthrough.pdf | ||

| + | |||

| + | |||

| + | '''Starting Info:''' | ||

| + | |||

| + | |||

| + | I did this swap with my 1981 AMC Eagle SX4. The Eagle originally came with the 4.2 Liter straight 6. | ||

| + | |||

| + | My donor motor was a 1999 Jeep Cherokee 4.0 Liter | ||

| + | |||

| + | Because it was a 1999 4.0 Liter, the following walkthrough can be used for anyone swapping a 1996 or newer 4.0 Liter. The reason being: | ||

| + | |||

| + | Pre 1996 is Renix and OBDI | ||

| + | Anything 1996 or newer is OBDII (mine) | ||

| + | |||

| + | '''When You Pull The Motor:''' | ||

| + | |||

| + | Make sure it does not have a security system… to do this you will need to call a local dealer and give them the vin number of the donor vehicle the 4.0 L is coming out of. With this number, the dealer will be able to tell you whether or not the vehicle came with the security system. If it has the security system, then you might as well give up on that wiring harness. If it does NOT have the security system, then you are good to go. You know you have a security system when you go to fire it up and it runs great for 3 seconds. (Ask me how I know) haha. | ||

| + | |||

| + | '''Make sure to get:''' | ||

| + | |||

| + | • The ENTIRE wiring harness that came with your 4.0 (do not cut any wires off of the harness, only disconnect the connectors) Some of the connectors are under the dash, so make sure not to just HACK away the harness from the engine compartment | ||

| + | • The Fuse box that is inside the engine compartment | ||

| + | • The Starter motor | ||

| + | • The PCM (computer) | ||

| + | • The intake and exhaust header | ||

| + | • And all other sensors on the intake and also the O2 Sensor on the header | ||

| + | • The C.P.S. (crankshaft position sensor) located on the bell-housing | ||

| + | |||

| + | *Note: Some people do a complete swap of drivelines: Engine, Tranny, and Transfer Case. By doing this you eliminate the problem of having to mount your C.P.S. to the 998 (Eagle) tranny and you also get the desired LOW range. However, you will need to shorten/lengthen the Eagles drive shafts due to the differing lengths of the 998 tranny and the donor vehicle’s tranny. There is also a good chance that the transfer case off of the donor vehicle has an “open” 4WD. You would be better off with a 229 transfer case that has a “viscous coupling”. | ||

| + | |||

| + | '''The Things They Don’t Tell You:''' | ||

| + | |||

| + | A lot of the information on the 4.0 Swap is found AFTER you’re half way into it… | ||

| + | |||

| + | '''• The Flex Plate:''' | ||

| + | |||

| + | If you pull your OBDII 4.0 L motor and are planning on attaching your Eagle’s 998 tranny to it, then you will most likely need a different flex plate than what the 4.0 came with. | ||

| + | |||

| + | What you will need is a 32RH/42RE Flex Plate. These flex plates came in 1991-1995 4.0 L Wranglers and late 1993-1996 4.0 L Grand Cherokees | ||

| + | |||

| + | '''• The Starter Motor:''' | ||

| + | |||

| + | The Eagle’s starter will not work with the new flew plate so make sure to get the new one off of the 4.0 donor | ||

| + | |||

| + | '''• The C.P.S.:''' | ||

| + | |||

| + | A sensor that requires some fabricating or 300 dollars to get it to work with your 998 Transmission. | ||

| + | |||

| + | • Expense: | ||

| + | |||

| + | Be prepared to spend a lot of money… just to give you an idea of how much… the fuel line alone will cost you approx 60 bucks. | ||

| + | |||

| + | '''• The Oil Pan:''' | ||

| + | |||

| + | You will need the oil pan off of your 4.2 because the one on the 4.0 will not clear the front axle (unless you have a strait axle already installed in your eagle) | ||

| + | |||

| + | '''FUEL:''' | ||

| + | |||

| + | '''• The Fuel Pump:''' | ||

| + | |||

| + | Because the 4.0 L is fuel injected you will need a fuel pump that is capable of at least 50 P.S.I. | ||

| + | |||

| + | I bought the most common pump: The “E2000” which is rated at 100 P.S.I. | ||

| + | |||

| + | Any in-line fuel pump capable of at least 50 P.S.I. should work fine. However, like many of the high-pressure in-line fuel pumps (E2000 included) they do not work well self priming. Meaning, if you ever run the tank out of gas it can be a royal to get the fuel to start pumping again. | ||

| + | |||

| + | A simple solution to this problem is mounting a self-priming in-line fuel pump that is rated for low pressure carbureted systems right before the high pressure pump. This will insure that the high pressure pump is always getting fuel. | ||

| + | |||

| + | I personally do not have a self-priming pump; I just mounted my E2000 at the same level as my gas tank and hoped for the best. I can drive till about 1/8 tank before I can hear my pump sucking air. I also get irregular “surging” during acceleration every once in a while, which I think is due to the fact that I don’t have a self-priming pump before my E2000. | ||

| + | |||

| + | '''• The Fuel Regulator:''' | ||

| + | |||

| + | OBDII 4.0’s require 49.5 P.S.I. of fuel pressure. The E2000 (and many other in-line pumps) dice out well over the 49.5 P.S.I. Therefore, you will need to regulate that pressure down to the 49.5 needed. | ||

| + | |||

| + | Some 4.0 L come with the fuel pressure regulator right on the fuel rail itself, so go check to see if you have one on the rail first. | ||

| + | |||

| + | If so, then that is one less thing you have to buy. | ||

| + | |||

| + | I didn’t have the regulator on the fuel rail so I went to my local dealership and asked them for the in-line fuel pressure regulator off of a Grand Cherokee. It cost me about 100 bucks. | ||

| + | |||

| + | '''• The Fuel Line:''' | ||

| + | |||

| + | Now that you have high pressure fuel you will need to replace your existing fuel line with fuel line rated for high pressure. | ||

| + | |||

| + | I bought two of the longest metal lines that my auto parts store carried and that took me a majority of the distance. | ||

| + | |||

| + | I then bought high pressure rubber fuel line to connect the gaps between the metal fuel lines and the pump/regulator/filter/fuel rail. This stuff is very expensive, so try to get a good estimate beforehand. | ||

| + | |||

| + | '''• The Fuel Filter:''' | ||

| + | |||

| + | Everyone has their own opinion on were and how to filter their gas, so this is how I did it: | ||

| + | |||

| + | I ran a low pressure (typical carbureted) fuel filter right BEFORE the high pressure pump. This keeps my pump from getting clogged and does the job of filtering. Not to mention it is a heck of a lot cheaper than a high pressure fuel filter. | ||

| + | |||

| + | The in-line fuel regulator that I bought also acts as a fuel filter, even though the fuel has already been filtered before the pump. It is not necessary to have a filter after the pump; it just turned out to be that way when I found out my regulator was also a filter. | ||

| + | |||

| + | '''• The Order:''' | ||

| + | |||

| + | This is MY order, and this order WORKS: | ||

| + | (From the Eagle’s tank to the 4.0 L’s fuel rail) | ||

| + | |||

| + | '''TANK''' | ||

| + | |||

| + | Low Pressure Rubber Fuel Line | ||

| + | |||

| + | Low Pressure Fuel Filter | ||

| + | |||

| + | E2000 Fuel Pump (aka In-Line High Pressure Fuel Pump) | ||

| + | |||

| + | High Pressure Rubber Fuel Line | ||

| + | |||

| + | In-Line Fuel Regulator | ||

| + | |||

| + | High Pressure Rubber Fuel Line | ||

| + | |||

| + | Metal Tube Fuel Line | ||

| + | |||

| + | High Pressure Rubber Fuel Line | ||

| + | |||

| + | |||

| + | '''FUEL RAIL''' | ||

| + | |||

| + | [[Image:jp001.jpg|center]] | ||

| + | |||

| + | |||

| + | [[Image:jp002.jpg|center]] | ||

| + | |||

| + | |||

| + | [[Image:jp003.jpg|center]] | ||

| + | |||

| + | |||

| + | [[Image:jp004.jpg|center]] | ||

| + | |||

| + | |||

| + | [[Image:jp005.jpg|center]] | ||

| + | |||

| + | |||

| + | [[Image:jp006.jpg|center]] | ||

| + | |||

| + | |||

| + | '''Dealing with the CRANKSHAFT POSITION SENSOR:''' | ||

| + | |||

| + | Any OBDII or OBDI 4.0 will need a C.P.S. (Crankshaft Position Sensor) in order to run. This sensor is mounted on the bellhousing of the donor vehicles transmission. The 998 Tranny that you AMC Eagle comes with DOES NOT HAVE a mount for this sensor. | ||

| + | |||

| + | You have two options…. | ||

| + | |||

| + | 1. Buy the re-locator kit from Hesco for about 300 bucks | ||

| + | |||

| + | 2. Make your own bracket… drill a hole in your 998 Tranny… and mount the C.P.S. onto your Eagles 998. | ||

| + | |||

| + | I don’t like spending money when I don’t have to so I chose to make my own bracket to mount the C.P.S. | ||

| + | |||

| + | Here is a link to the sight I posted pictures and info as to how this can be done: | ||

| + | |||

| + | http://www.cjoffroad.com/forums/topic.asp?TOPIC_ID=8076&SearchTerms=c.p.s | ||

| + | |||

| + | |||

| + | '''Vehicle Speed Sensor?''' | ||

| + | |||

| + | This is a touchy topic… Half of the people that have done the swap will tell you that the V.S.S. is pointless and the other half will tell you that it makes a world of difference. | ||

| + | |||

| + | From my own experience: | ||

| + | |||

| + | I drove my 4.0 around for 6 months WITHOUT it and then installed one and have been driving it around ever since. I have noticed NO difference at all. So if I were you I wouldn’t worry about the V.S.S. for now… Worry about getting the thing running first. | ||

| + | |||

| + | '''CLEARANCE ISSUES:''' | ||

| + | |||

| + | Not everything fits just right as you will eventually find out. My goal here is to tell you everything that needs to be made/modified in order to fit BEFORE you try lowing that 4.0 L into your Eagle. I had to pull my 4.0 in and out 3 times before I found and solved every clearance issue. | ||

| + | |||

| + | First…. The alternator will hit the top bolt of that steering bracket. (I don’t know the technical name of that bracket) but here is a picture and you could locate the nut just by looking into you engine compartment and picturing were the alternator will lay. A simple fix to this problem is to grind a little off of the alternator and a little more off of that bolt (still leaving a little bit of the head all the way around so that if you ever need to take it off you still can)… not that you are going to have to though. | ||

| + | |||

| + | |||

| + | [[Image:jp007.jpg|center]] | ||

| + | |||

| + | |||

| + | The next clearance issue is the BATTERY. If you decide to keep the 4.0 L fan on the motor then you will notice that the fan is offset to one side of the motor. Offset just enough to hit you battery tray when you try to crank the motor over. I simply cut my battery tray down a little bit (because I had a narrow battery that measured 5.75 inches wide). After cutting the battery tray to the point were it had a clearance of approx half an inch from the fan I then welded on a piece of sheet metal to ensure that the battery will never run itself into the fan… here is a picture of the now custom battery tray that you will have to make in order to clear the 4.0 L fan. | ||

| + | |||

| + | |||

| + | [[Image:jp008.jpg|center]] | ||

| + | |||

| + | |||

| + | The OIL PAN on the 4.0 L WILL NOT WORK ! It will hit the front Axle… and don’t bother trying to heat it up and hammer it. I did and it was a waste of 4 hours upside down under my car. Not to mention…. The inside of your oil pan will flake steel when you hit it with a hammer. So…. BEFORE you put the 4.0 into your Eagle make sure to put the 4.2 L oil pan on it… and in order to do this you must either BEND the 4.0 L oil pick-up tube or replace it with the oil pick-up tube out of your 4.2 L. I think I just bent mine to fit (but make sure it isn’t going to be too close to the bottom of you pan, or you will not get enough oil pressure and destroy your new motor. | ||

| + | |||

| + | The EXHAUST will also give you problems. Don’t bother trying to buy a different header for the 4.0… because none of them will fit any better than the stock 4.0 L exhaust manifold. There are TWO main issues with the exhaust coming off of a 4.0 L. | ||

| + | The first issue is that the header flange hits the vertically mounted bracket that holds up your front differential. A simple fix to this is to grind away at the bracket till you have enough clearance. You will also need to grind away slightly on the opposite side to get the bracket to fit flush on the engine block. After you grind away you can weld up some extra support to make up for weakening the bracket. Or you can just use the weakened bracket because I’m pretty sure it is still more than strong enough to support that front diff. Keep in mind that some people have used rebar and spacers in order to get the desired bracket. I just cut and welded mine because I like to overkill everything. | ||

| + | The second issue you will have with the 4.0 L exhaust is trying to run it around your Eagles front Diff. It is a P.I.T.A. but I was able to do it by cutting angles out of the old exhaust and guessing and checking until I got the exhaust to wrap around the front diff. ( I was actually able to do all of the exhaust fabricating with the old 4.2 L exhaust and did not need to buy any more tubing at all) | ||

| + | |||

| + | Here is a picture of the exhaust I had to make and the Bracket I had to grind in order to get that 4.0 L header to work: | ||

| + | |||

| + | |||

| + | [[Image:jp009.jpg|center]] | ||

| + | |||

| + | |||

| + | [[Image:jp010.jpg|center]] | ||

| + | |||

| + | |||

| + | [[Image:jp011.jpg|center]] | ||

| + | |||

| + | |||

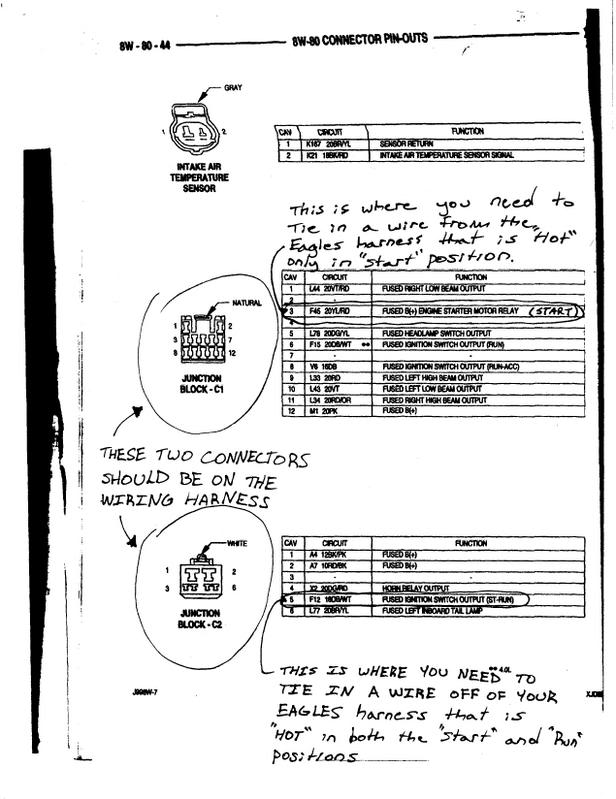

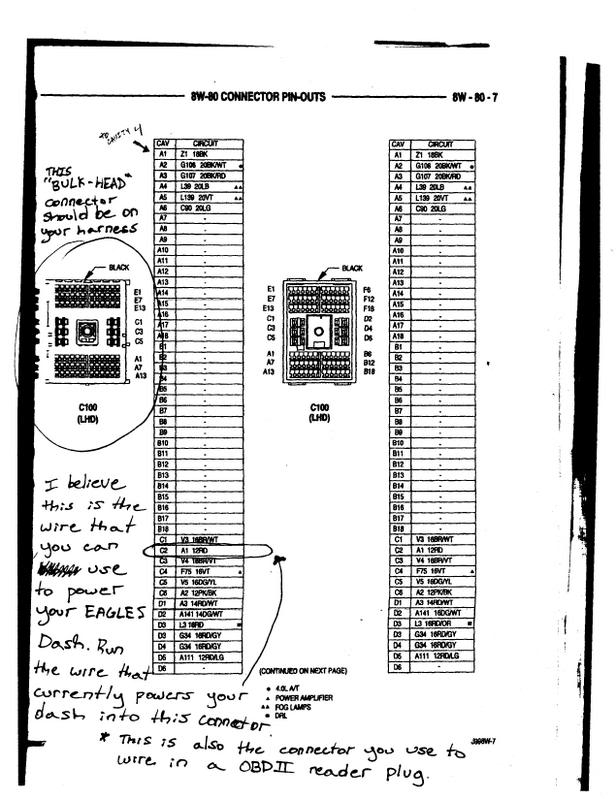

| + | '''ELECTICAL… ( Oh GOD! )''' | ||

| + | |||

| + | Ok, first of all… it isn’t THAT bad. I just don’t want to have to run through all of this all over again just to help one of you out. First thing is first: | ||

| + | GET THE SHOP MANUAL FOR YOUR DONOR VEHICLE… it will make the electrical portion of this swap 100 times easier. The shop manuals can be found online if you look hard enough. If you happen to have a 1999 Jeep Cherokee motor then you can use the following pictures and possibly go without buying the manual. | ||

| + | |||

| + | I can’t help you that much on this section of the 4.0 Swap… because I can’t tell you exactly were each wire is and were each wire needs to be spliced. | ||

| + | |||

| + | I can tell you which wires need to be located and were they need to go… approx. | ||

| + | |||

| + | '''First off:''' | ||

| + | |||

| + | The following wires on the 4.0 Harness need to be located: | ||

| + | |||

| + | • Fuel Pump + (this is run directly to the e2000 fuel pump) | ||

| + | |||

| + | • Fuel Pump – (this is also run directly to the e2000 fuel pump) | ||

| + | |||

| + | • Transmission Neutral Safety Switch (-) (can be run to the connector on the 998 tranny itself) | ||

| + | |||

| + | • Main Power Supply to Dash (+) (your new power supply to your Eagles Dash) | ||

| + | |||

| + | • Ignition “start” (this needs to tie into the corresponding wire in your Eagles wiring harness) | ||

| + | |||

| + | • Ignition “Start + run” (this also needs to be tied into the corresponding wire in you Eagles wiring harness) | ||

| + | |||

| + | |||

| + | The following wires on your Eagles harness need to be located: | ||

| + | |||

| + | • Ignition “Start” | ||

| + | |||

| + | • Ignition “Start + Run” | ||

| + | |||

| + | • Main Power Supply to Dash | ||

| + | |||

| + | • Neutral Safety Switch Wire *this one can actually be run from the center node on your 998 transmission’s wire connector. Located directly on the transmission itself (it is a round connector with three wires running out of it…. If you pull it off then you will be able to see the three “nodes” that I am referring to. The Center node is the Neutral Safety Switch wire that needs to be routed into the 4.0 L wiring harness). | ||

| + | |||

| + | '''HELPFUL HINT:''' | ||

| + | |||

| + | It helps to leave ALL of the 4.0 L connectors in tact… when I say “tie into” I actually mean find the wire that needs to connect to that pin in the connector and buy the right size fit (male or female) to fit into that pin. | ||

| + | |||

| + | Leaving the connectors on the 4.0 Wiring harness makes it a LOT easier to ever re-locate that specific connector and all of the wires that run through that connector. | ||

| + | I left the connector heads on, tied the correct wires from the Eagle into it with male or female connectors and black-taped the one or two wires from the Eagle with the entire 4.0 connector head as one piece. | ||

| + | |||

| + | You only need to locate 4 or 5 connector heads on the 4.0 harness in order to find all of the wires you will need. Here are a few of those connectors I can remember | ||

| + | |||

| + | |||

| + | [[Image:jp012.jpg|center]] | ||

| + | |||

| + | |||

| + | [[Image:jp013.jpg|center]] | ||

| + | |||

| + | |||

| + | <center>THE END… Feel free to offer me free eagle parts if this was a huge help. Ha-Ha | ||

| + | |||

| + | Joshua Tulberg | ||

| + | |||

| + | [email protected] </center> | ||

Latest revision as of 16:41, 15 November 2009

By AMC Eagle Nest Member Joshpit

She will ask for knobby tires.

A complete Walkthrough for swapping a 4.0 into an AMC Eagle

By: Joshua Tulberg

[email protected]Here is the printable pdf version:

http://www.amceaglenest.com/images/PDFS/Joshs%204.0%20Walkthrough.pdf

Starting Info:

I did this swap with my 1981 AMC Eagle SX4. The Eagle originally came with the 4.2 Liter straight 6.

My donor motor was a 1999 Jeep Cherokee 4.0 Liter

Because it was a 1999 4.0 Liter, the following walkthrough can be used for anyone swapping a 1996 or newer 4.0 Liter. The reason being:

Pre 1996 is Renix and OBDI Anything 1996 or newer is OBDII (mine)

When You Pull The Motor:

Make sure it does not have a security system… to do this you will need to call a local dealer and give them the vin number of the donor vehicle the 4.0 L is coming out of. With this number, the dealer will be able to tell you whether or not the vehicle came with the security system. If it has the security system, then you might as well give up on that wiring harness. If it does NOT have the security system, then you are good to go. You know you have a security system when you go to fire it up and it runs great for 3 seconds. (Ask me how I know) haha.

Make sure to get:

• The ENTIRE wiring harness that came with your 4.0 (do not cut any wires off of the harness, only disconnect the connectors) Some of the connectors are under the dash, so make sure not to just HACK away the harness from the engine compartment • The Fuse box that is inside the engine compartment • The Starter motor • The PCM (computer) • The intake and exhaust header • And all other sensors on the intake and also the O2 Sensor on the header • The C.P.S. (crankshaft position sensor) located on the bell-housing

- Note: Some people do a complete swap of drivelines: Engine, Tranny, and Transfer Case. By doing this you eliminate the problem of having to mount your C.P.S. to the 998 (Eagle) tranny and you also get the desired LOW range. However, you will need to shorten/lengthen the Eagles drive shafts due to the differing lengths of the 998 tranny and the donor vehicle’s tranny. There is also a good chance that the transfer case off of the donor vehicle has an “open” 4WD. You would be better off with a 229 transfer case that has a “viscous coupling”.

The Things They Don’t Tell You:

A lot of the information on the 4.0 Swap is found AFTER you’re half way into it…

• The Flex Plate:

If you pull your OBDII 4.0 L motor and are planning on attaching your Eagle’s 998 tranny to it, then you will most likely need a different flex plate than what the 4.0 came with.

What you will need is a 32RH/42RE Flex Plate. These flex plates came in 1991-1995 4.0 L Wranglers and late 1993-1996 4.0 L Grand Cherokees

• The Starter Motor:

The Eagle’s starter will not work with the new flew plate so make sure to get the new one off of the 4.0 donor

• The C.P.S.:

A sensor that requires some fabricating or 300 dollars to get it to work with your 998 Transmission.

• Expense:

Be prepared to spend a lot of money… just to give you an idea of how much… the fuel line alone will cost you approx 60 bucks.

• The Oil Pan:

You will need the oil pan off of your 4.2 because the one on the 4.0 will not clear the front axle (unless you have a strait axle already installed in your eagle)

FUEL:

• The Fuel Pump:

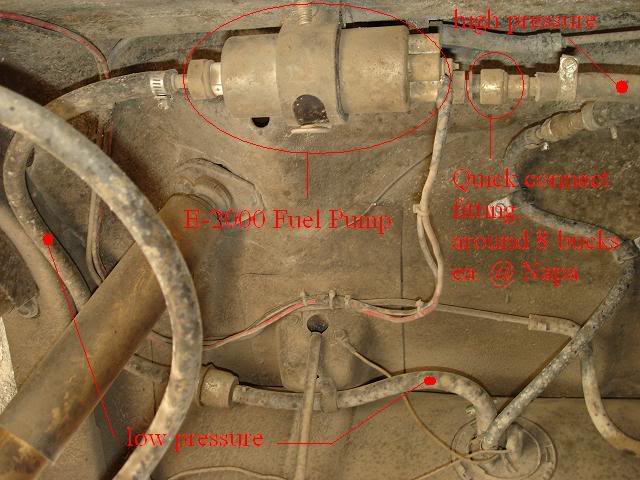

Because the 4.0 L is fuel injected you will need a fuel pump that is capable of at least 50 P.S.I.

I bought the most common pump: The “E2000” which is rated at 100 P.S.I.

Any in-line fuel pump capable of at least 50 P.S.I. should work fine. However, like many of the high-pressure in-line fuel pumps (E2000 included) they do not work well self priming. Meaning, if you ever run the tank out of gas it can be a royal to get the fuel to start pumping again.

A simple solution to this problem is mounting a self-priming in-line fuel pump that is rated for low pressure carbureted systems right before the high pressure pump. This will insure that the high pressure pump is always getting fuel.

I personally do not have a self-priming pump; I just mounted my E2000 at the same level as my gas tank and hoped for the best. I can drive till about 1/8 tank before I can hear my pump sucking air. I also get irregular “surging” during acceleration every once in a while, which I think is due to the fact that I don’t have a self-priming pump before my E2000.

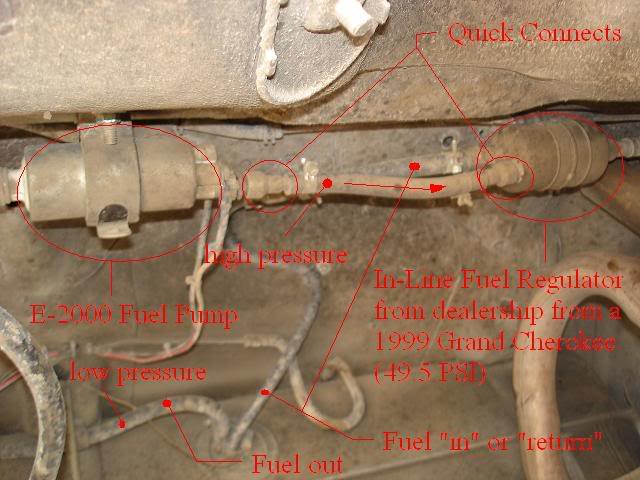

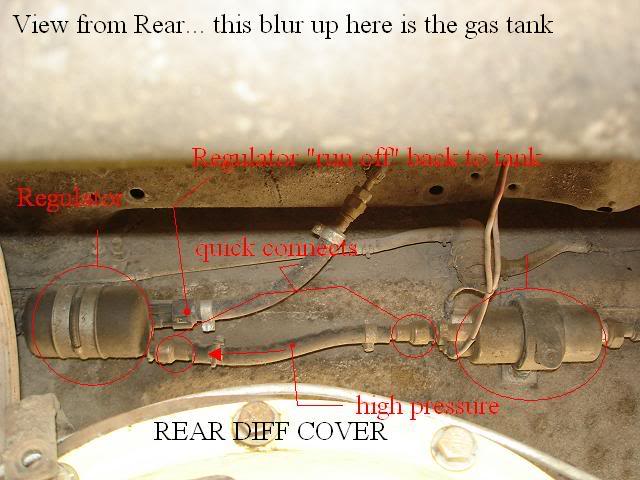

• The Fuel Regulator:

OBDII 4.0’s require 49.5 P.S.I. of fuel pressure. The E2000 (and many other in-line pumps) dice out well over the 49.5 P.S.I. Therefore, you will need to regulate that pressure down to the 49.5 needed.

Some 4.0 L come with the fuel pressure regulator right on the fuel rail itself, so go check to see if you have one on the rail first.

If so, then that is one less thing you have to buy.

I didn’t have the regulator on the fuel rail so I went to my local dealership and asked them for the in-line fuel pressure regulator off of a Grand Cherokee. It cost me about 100 bucks.

• The Fuel Line:

Now that you have high pressure fuel you will need to replace your existing fuel line with fuel line rated for high pressure.

I bought two of the longest metal lines that my auto parts store carried and that took me a majority of the distance.

I then bought high pressure rubber fuel line to connect the gaps between the metal fuel lines and the pump/regulator/filter/fuel rail. This stuff is very expensive, so try to get a good estimate beforehand.

• The Fuel Filter:

Everyone has their own opinion on were and how to filter their gas, so this is how I did it:

I ran a low pressure (typical carbureted) fuel filter right BEFORE the high pressure pump. This keeps my pump from getting clogged and does the job of filtering. Not to mention it is a heck of a lot cheaper than a high pressure fuel filter.

The in-line fuel regulator that I bought also acts as a fuel filter, even though the fuel has already been filtered before the pump. It is not necessary to have a filter after the pump; it just turned out to be that way when I found out my regulator was also a filter.

• The Order:

This is MY order, and this order WORKS: (From the Eagle’s tank to the 4.0 L’s fuel rail)

TANK

Low Pressure Rubber Fuel Line

Low Pressure Fuel Filter

E2000 Fuel Pump (aka In-Line High Pressure Fuel Pump)

High Pressure Rubber Fuel Line

In-Line Fuel Regulator

High Pressure Rubber Fuel Line

Metal Tube Fuel Line

High Pressure Rubber Fuel Line

FUEL RAIL

Dealing with the CRANKSHAFT POSITION SENSOR:

Any OBDII or OBDI 4.0 will need a C.P.S. (Crankshaft Position Sensor) in order to run. This sensor is mounted on the bellhousing of the donor vehicles transmission. The 998 Tranny that you AMC Eagle comes with DOES NOT HAVE a mount for this sensor.

You have two options….

1. Buy the re-locator kit from Hesco for about 300 bucks

2. Make your own bracket… drill a hole in your 998 Tranny… and mount the C.P.S. onto your Eagles 998.

I don’t like spending money when I don’t have to so I chose to make my own bracket to mount the C.P.S.

Here is a link to the sight I posted pictures and info as to how this can be done:

http://www.cjoffroad.com/forums/topic.asp?TOPIC_ID=8076&SearchTerms=c.p.s

Vehicle Speed Sensor?

This is a touchy topic… Half of the people that have done the swap will tell you that the V.S.S. is pointless and the other half will tell you that it makes a world of difference.

From my own experience:

I drove my 4.0 around for 6 months WITHOUT it and then installed one and have been driving it around ever since. I have noticed NO difference at all. So if I were you I wouldn’t worry about the V.S.S. for now… Worry about getting the thing running first.

CLEARANCE ISSUES:

Not everything fits just right as you will eventually find out. My goal here is to tell you everything that needs to be made/modified in order to fit BEFORE you try lowing that 4.0 L into your Eagle. I had to pull my 4.0 in and out 3 times before I found and solved every clearance issue.

First…. The alternator will hit the top bolt of that steering bracket. (I don’t know the technical name of that bracket) but here is a picture and you could locate the nut just by looking into you engine compartment and picturing were the alternator will lay. A simple fix to this problem is to grind a little off of the alternator and a little more off of that bolt (still leaving a little bit of the head all the way around so that if you ever need to take it off you still can)… not that you are going to have to though.

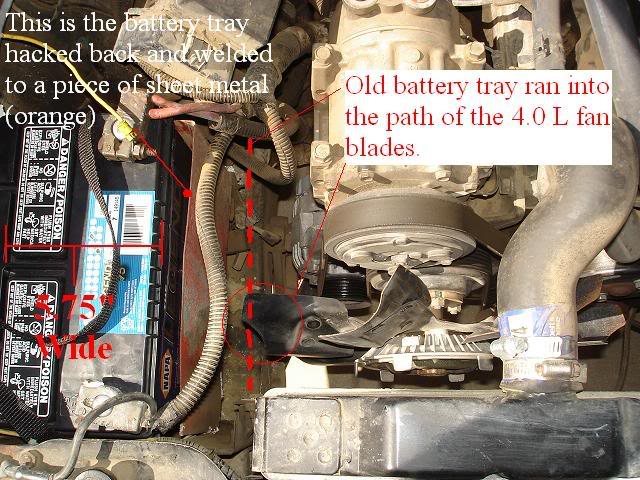

The next clearance issue is the BATTERY. If you decide to keep the 4.0 L fan on the motor then you will notice that the fan is offset to one side of the motor. Offset just enough to hit you battery tray when you try to crank the motor over. I simply cut my battery tray down a little bit (because I had a narrow battery that measured 5.75 inches wide). After cutting the battery tray to the point were it had a clearance of approx half an inch from the fan I then welded on a piece of sheet metal to ensure that the battery will never run itself into the fan… here is a picture of the now custom battery tray that you will have to make in order to clear the 4.0 L fan.

The OIL PAN on the 4.0 L WILL NOT WORK ! It will hit the front Axle… and don’t bother trying to heat it up and hammer it. I did and it was a waste of 4 hours upside down under my car. Not to mention…. The inside of your oil pan will flake steel when you hit it with a hammer. So…. BEFORE you put the 4.0 into your Eagle make sure to put the 4.2 L oil pan on it… and in order to do this you must either BEND the 4.0 L oil pick-up tube or replace it with the oil pick-up tube out of your 4.2 L. I think I just bent mine to fit (but make sure it isn’t going to be too close to the bottom of you pan, or you will not get enough oil pressure and destroy your new motor.

The EXHAUST will also give you problems. Don’t bother trying to buy a different header for the 4.0… because none of them will fit any better than the stock 4.0 L exhaust manifold. There are TWO main issues with the exhaust coming off of a 4.0 L. The first issue is that the header flange hits the vertically mounted bracket that holds up your front differential. A simple fix to this is to grind away at the bracket till you have enough clearance. You will also need to grind away slightly on the opposite side to get the bracket to fit flush on the engine block. After you grind away you can weld up some extra support to make up for weakening the bracket. Or you can just use the weakened bracket because I’m pretty sure it is still more than strong enough to support that front diff. Keep in mind that some people have used rebar and spacers in order to get the desired bracket. I just cut and welded mine because I like to overkill everything. The second issue you will have with the 4.0 L exhaust is trying to run it around your Eagles front Diff. It is a P.I.T.A. but I was able to do it by cutting angles out of the old exhaust and guessing and checking until I got the exhaust to wrap around the front diff. ( I was actually able to do all of the exhaust fabricating with the old 4.2 L exhaust and did not need to buy any more tubing at all)

Here is a picture of the exhaust I had to make and the Bracket I had to grind in order to get that 4.0 L header to work:

ELECTICAL… ( Oh GOD! )

Ok, first of all… it isn’t THAT bad. I just don’t want to have to run through all of this all over again just to help one of you out. First thing is first: GET THE SHOP MANUAL FOR YOUR DONOR VEHICLE… it will make the electrical portion of this swap 100 times easier. The shop manuals can be found online if you look hard enough. If you happen to have a 1999 Jeep Cherokee motor then you can use the following pictures and possibly go without buying the manual.

I can’t help you that much on this section of the 4.0 Swap… because I can’t tell you exactly were each wire is and were each wire needs to be spliced.

I can tell you which wires need to be located and were they need to go… approx.

First off:

The following wires on the 4.0 Harness need to be located:

• Fuel Pump + (this is run directly to the e2000 fuel pump)

• Fuel Pump – (this is also run directly to the e2000 fuel pump)

• Transmission Neutral Safety Switch (-) (can be run to the connector on the 998 tranny itself)

• Main Power Supply to Dash (+) (your new power supply to your Eagles Dash)

• Ignition “start” (this needs to tie into the corresponding wire in your Eagles wiring harness)

• Ignition “Start + run” (this also needs to be tied into the corresponding wire in you Eagles wiring harness)

The following wires on your Eagles harness need to be located:

• Ignition “Start”

• Ignition “Start + Run”

• Main Power Supply to Dash

• Neutral Safety Switch Wire *this one can actually be run from the center node on your 998 transmission’s wire connector. Located directly on the transmission itself (it is a round connector with three wires running out of it…. If you pull it off then you will be able to see the three “nodes” that I am referring to. The Center node is the Neutral Safety Switch wire that needs to be routed into the 4.0 L wiring harness).

HELPFUL HINT:

It helps to leave ALL of the 4.0 L connectors in tact… when I say “tie into” I actually mean find the wire that needs to connect to that pin in the connector and buy the right size fit (male or female) to fit into that pin.

Leaving the connectors on the 4.0 Wiring harness makes it a LOT easier to ever re-locate that specific connector and all of the wires that run through that connector. I left the connector heads on, tied the correct wires from the Eagle into it with male or female connectors and black-taped the one or two wires from the Eagle with the entire 4.0 connector head as one piece.

You only need to locate 4 or 5 connector heads on the 4.0 harness in order to find all of the wires you will need. Here are a few of those connectors I can remember

Joshua Tulberg

[email protected]